|

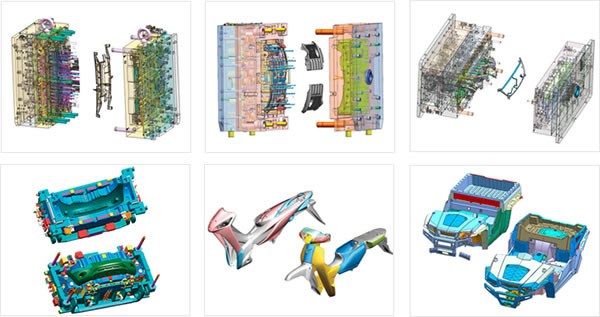

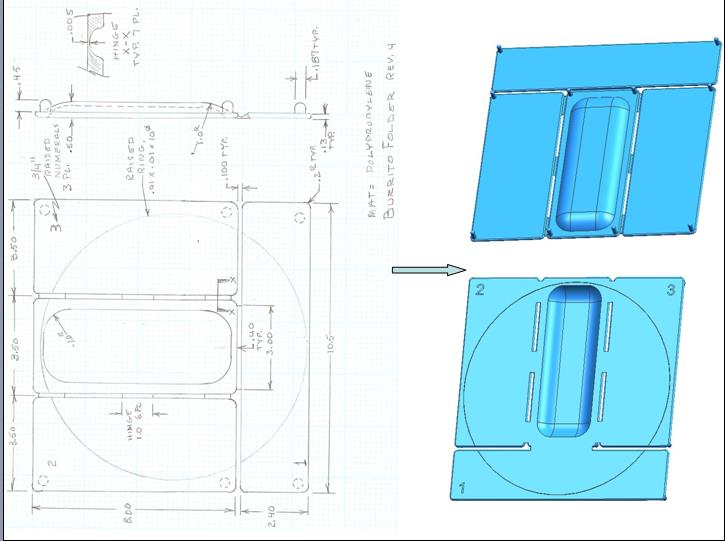

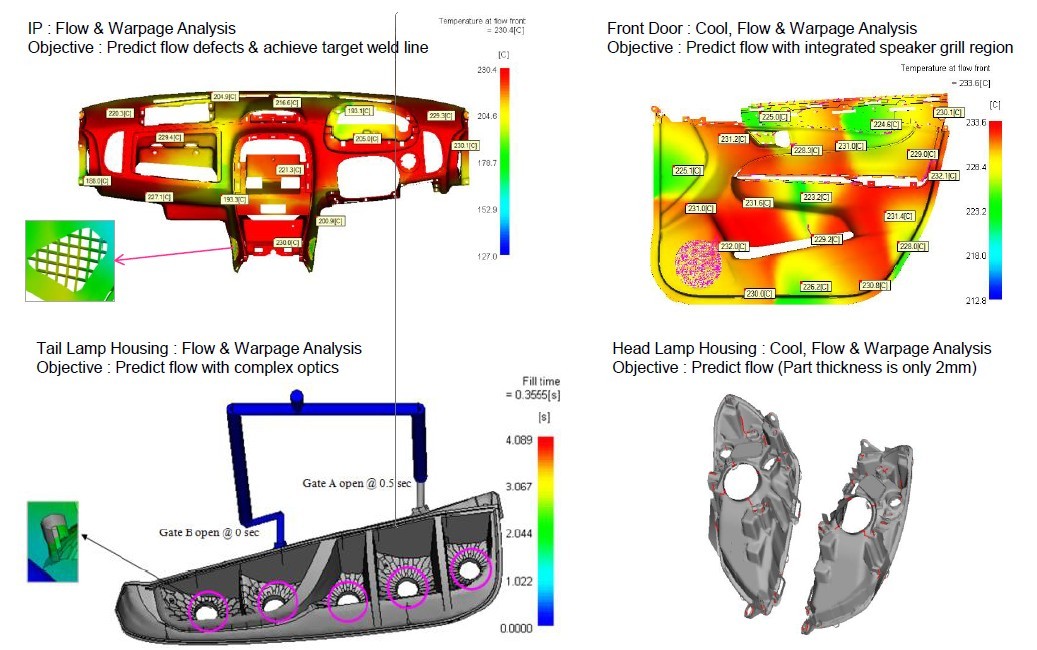

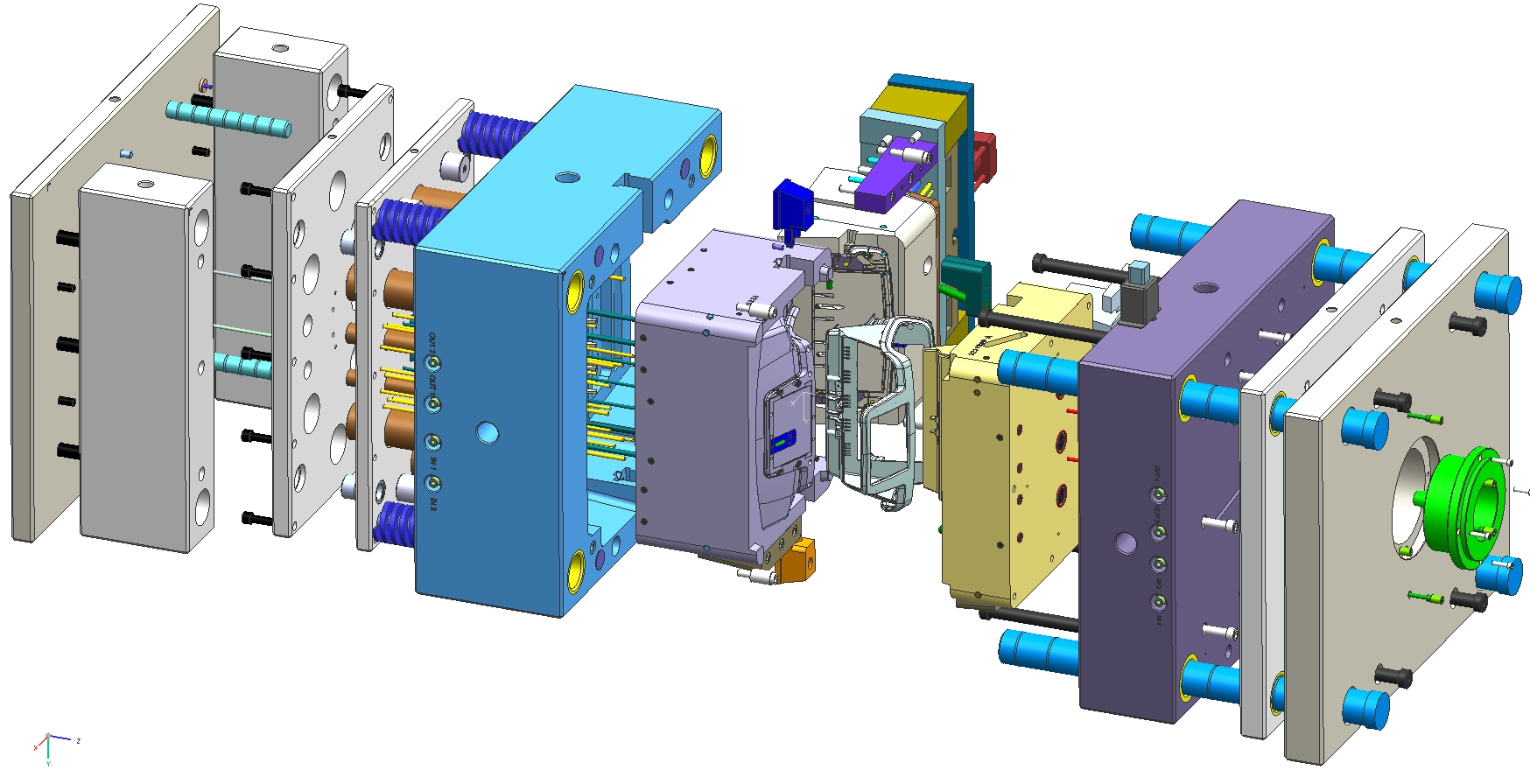

DESIGN & ENGINEERING Plastic Part Design, Engineering & 3D Modeling

Whether you have some initial design drawings,a picture, or just a simple concept in your head, XD MOULD can take your product from idea to reality.

|

FAQs

Excellent Reputation And Highly Customer Recognition.

- One-stop solution with best price

- Thanks to our skilled, talented and engaged employees ,and having fully equipped advanced facilities, we are able to offer one stop solutions: parts & components machining, design and engineering, mould making, mould trial, plastic moulding, packing and shipping. Every steps of your project is under one roof, ensuring better control of quality, schedule and cost.

- Focus on quality

- Quality is a mindset. At XD MOULD, quality is everyone’s responsibility and we never have to stop getting better. Our people are our most valuable resource. We don’t just hire good technicians,we hire good people we can count on. And those good people need good tools to create the quality products. At XD MOULD, we continually invest in the latest technology & equipment, and constantly improve our quality management system to pursue better quality.

HOME

HOME

PRODUCTS

PRODUCTS

SERVICES

SERVICES

CONTACTS

CONTACTS