|

|

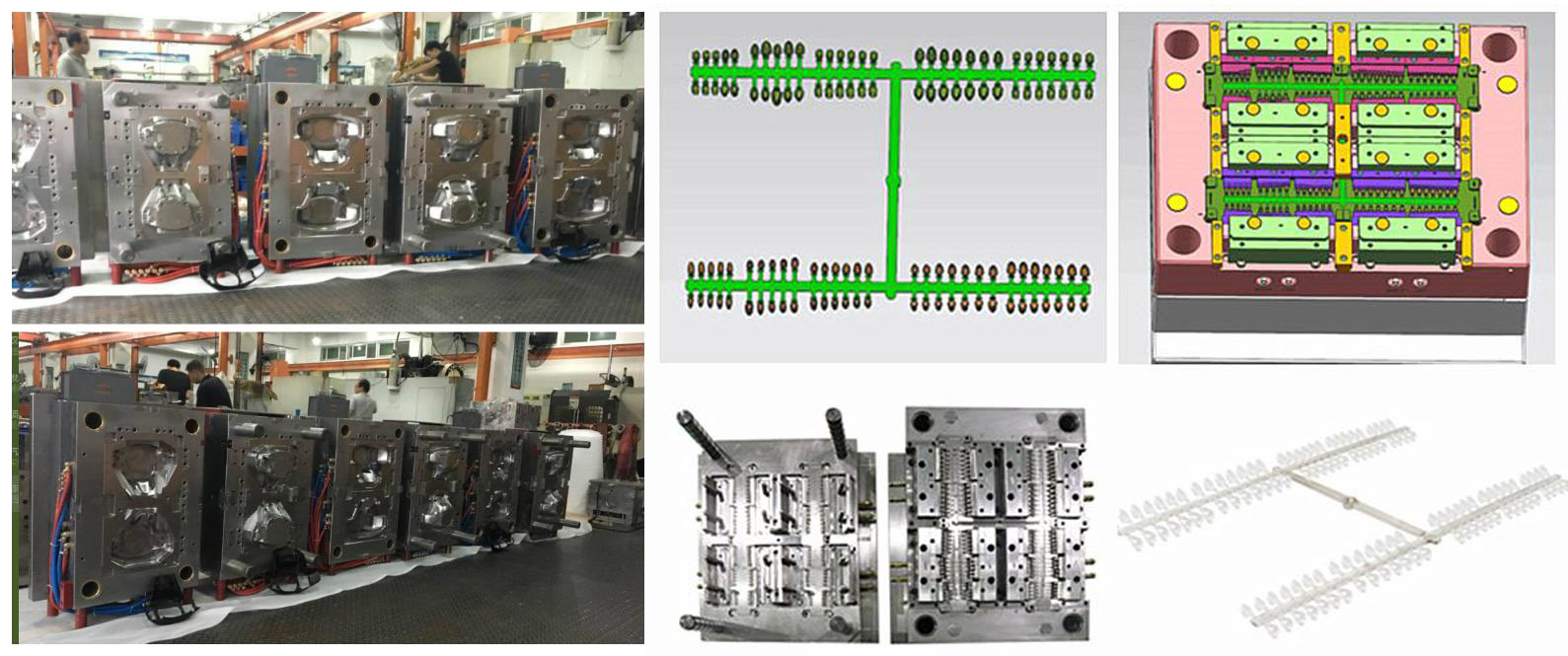

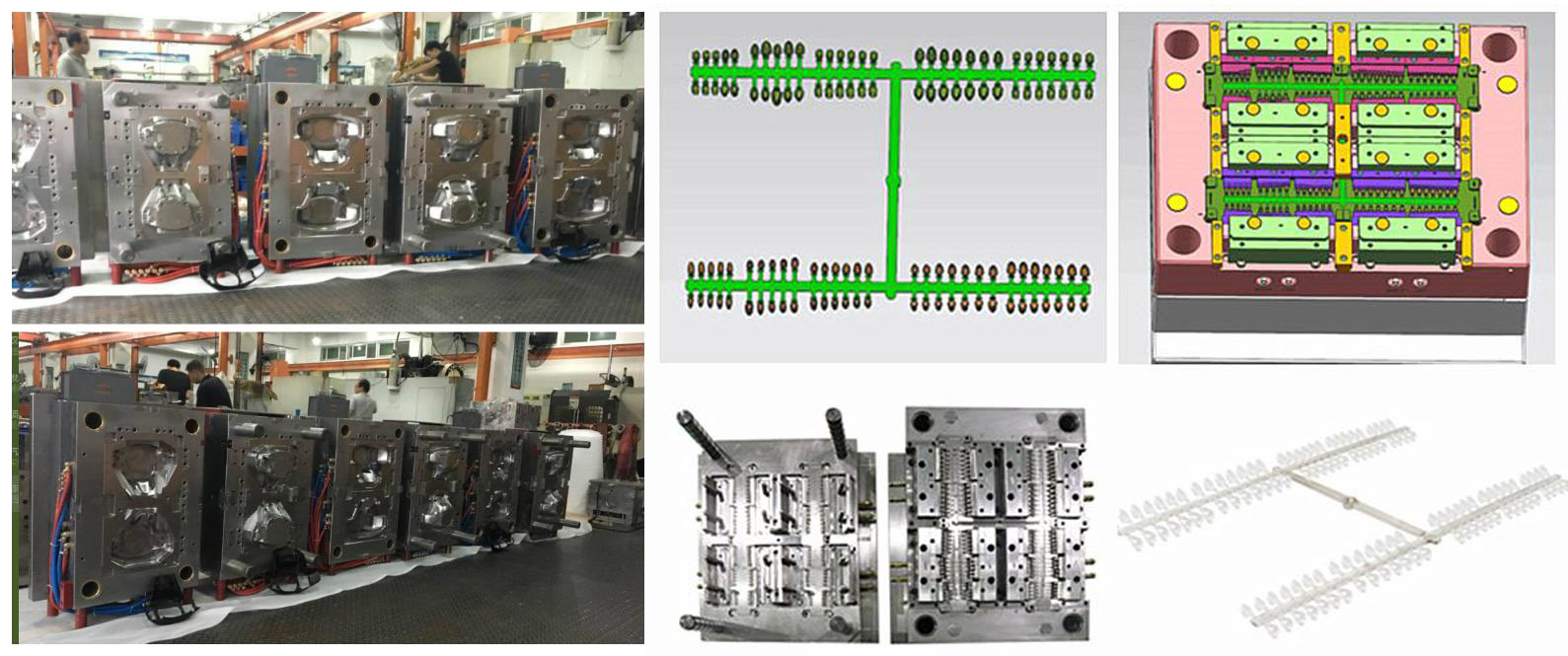

MOULD MAKING

All moulds manufactured at XD MOULD are designed and fully engineered as complete 3D Assembly Models using the state of the art CAD/CAM software.

Detailed design reviews and check-offs are integral to our process.Our project management team leading by the boss, review each mould designs, working along with the engineers to ensure accurate manufacturing scheme with best possible outcome.

|

|

|

With all product development details engineered, designed, and reviewed, every step of the manufacturing sequences are streamlined, enabling us to respond to tight schedules much more quickly and efficiently.

Our full in-house mould making operations are vertically integrated, with little or no outsourcing required other than for specialized heat treating, certain textures, or in some special cases,such as extremely urgent schedule of customer’s project.

|

|

Standard Process:

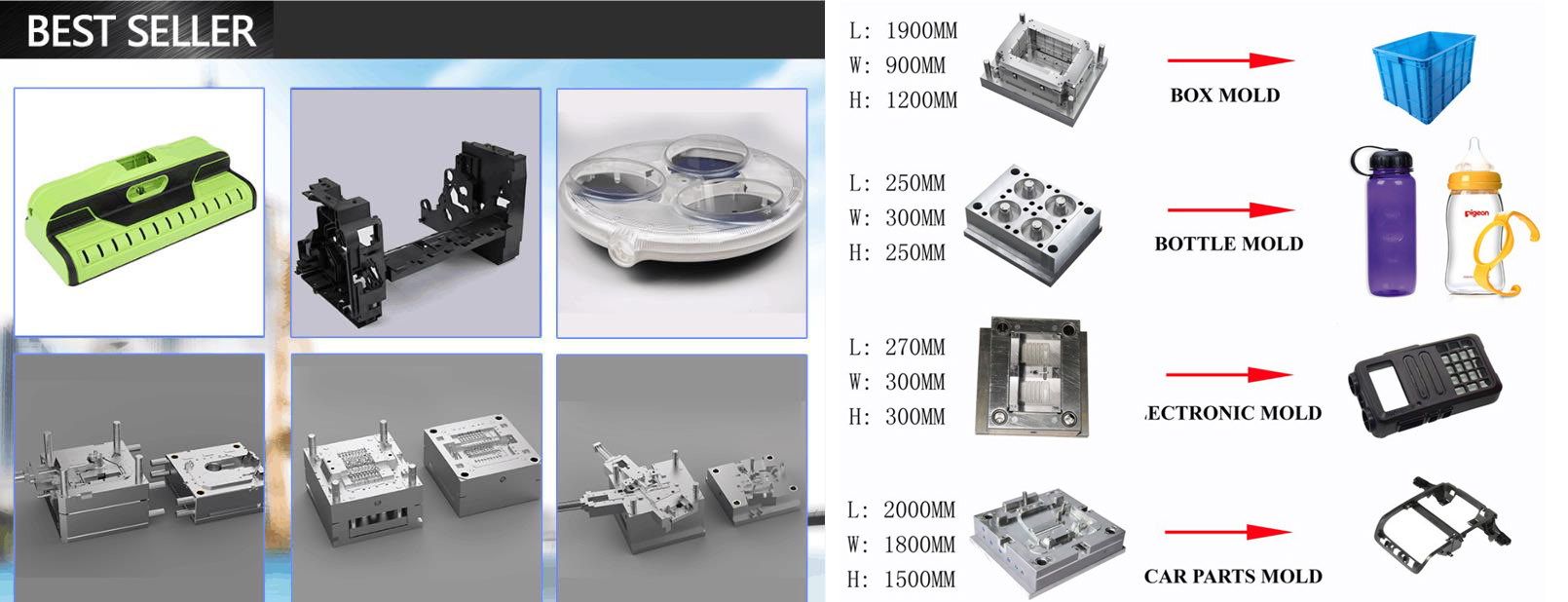

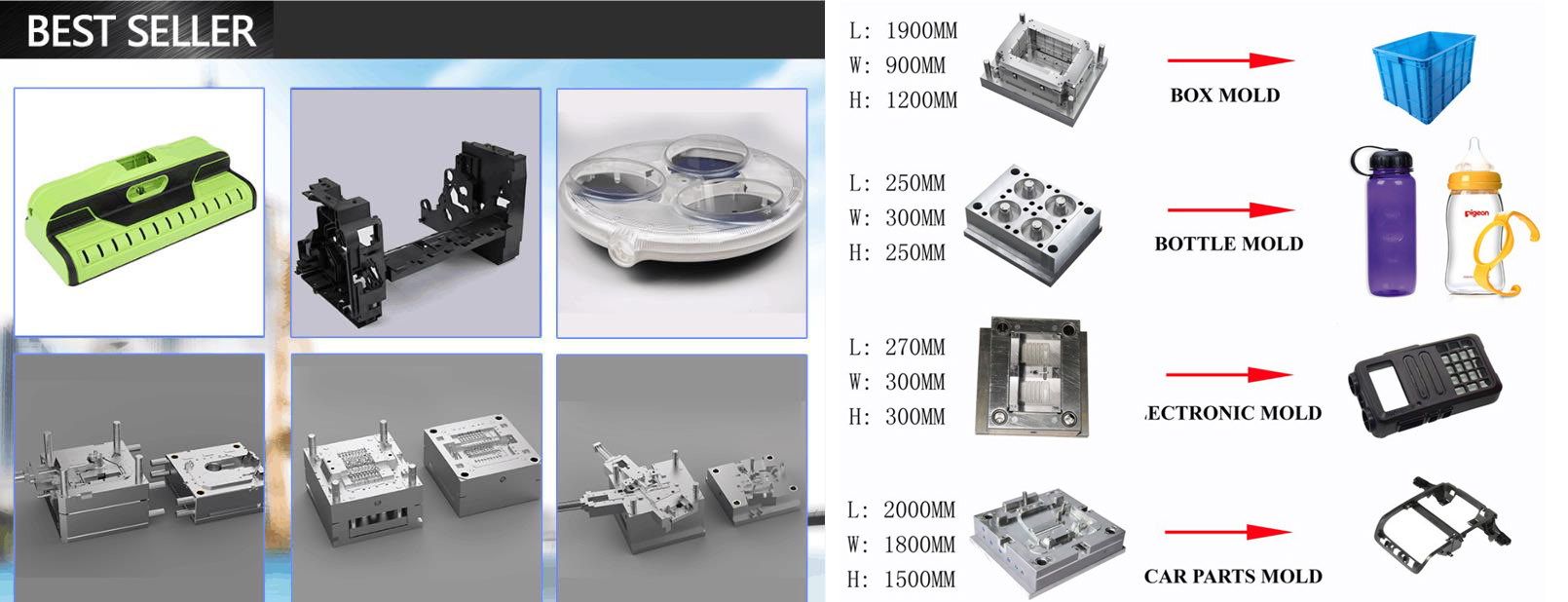

Design

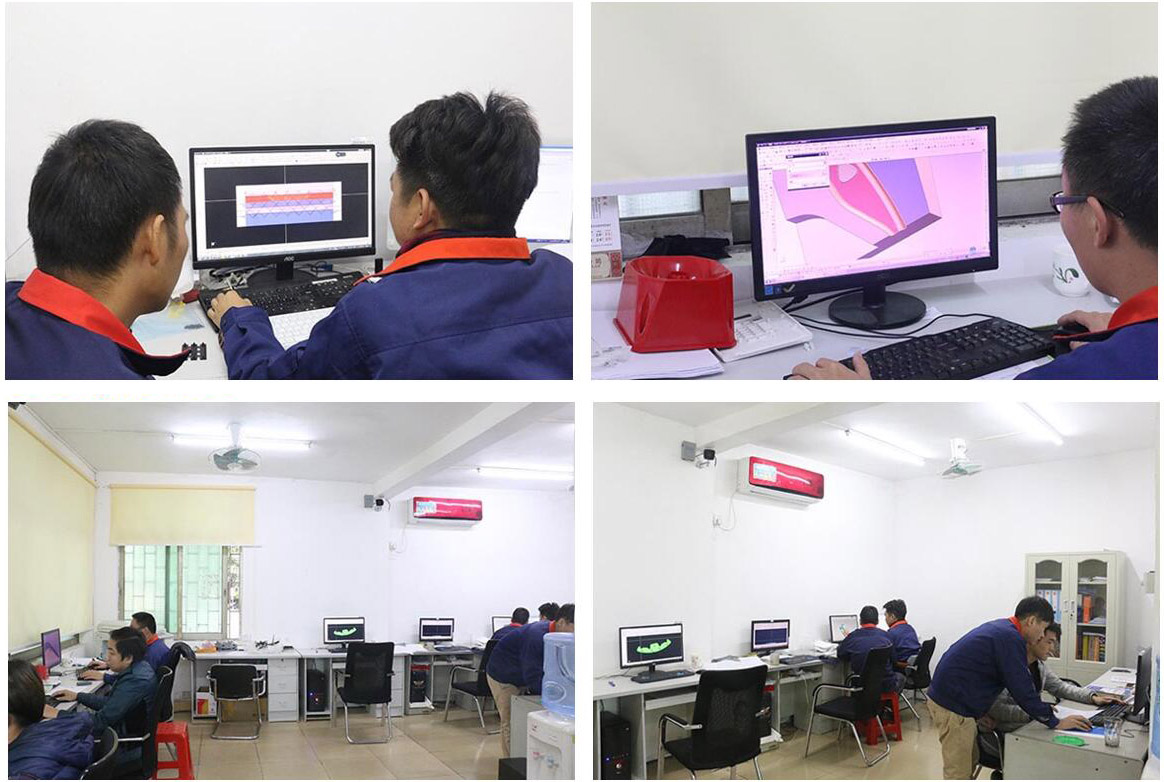

The engineering department ( 6 x Work Station ) designs injection moulds for all kinds of thermoplastics.

Our Capabilites:

1. Product Design and Development

2. Reverse Engineering

3. Injection Mould Design:

Unscrewing / Two Shot / Compound Slide

Hot Manifold / Three Plate / Internal Heat Manifold

4. Aluminum Die Design

5.Zinc Die Design

6.Mould Flow Analysis

|

|

|

Steel Preparation

Once design is finalized and final drawing is approved by customer, steel & mould base & standard components preparation begins.

We consistently use the high-standard steel material and mould bases to meet customers’ high-quality expectations. The CMTR (Certified Material Test Report) and Heat Treatment Report will be offered.

|

|

|

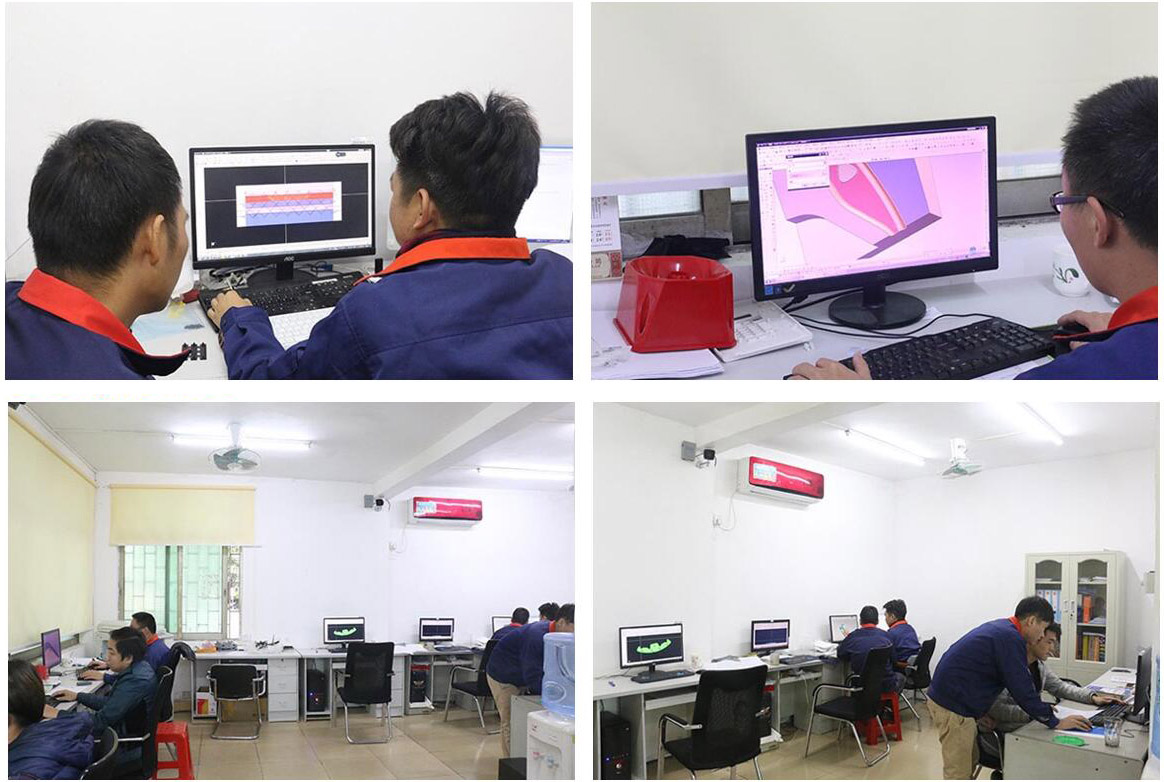

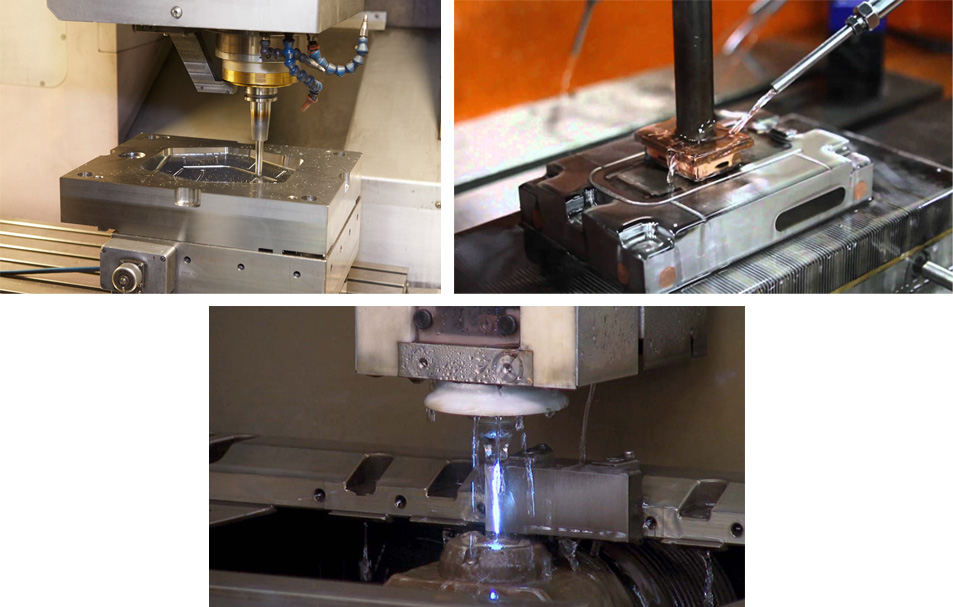

Rough Machining

As soon as the mould base arrives, rough machining begins.Our project managers will update project’s information to keep everyone involved on the same page and send Weekly Progress Report with detailed photos to keep the customers informed.

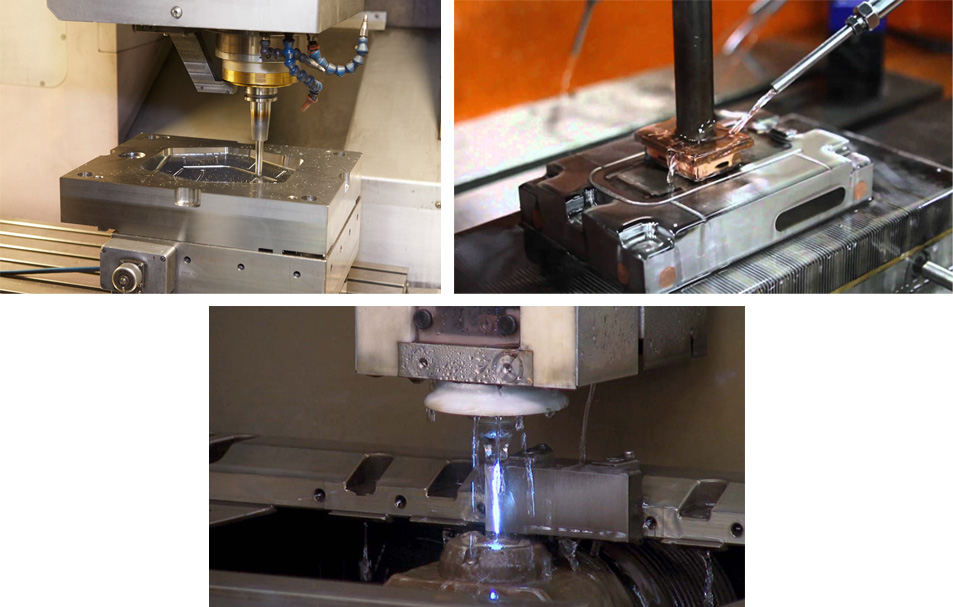

Precision Machining

Our machining department will utilize high speed CNC machinery, sink EDM,wire EDM and related precision facilities to build high precision parts and whole set of mould. A complete set of Mould Parts Inspection Report will be offered.

|

|

|

Polishing and Fitting

Once the mould has been precision machined, it’s finely polished to remove all machining and grinding marks. Ensuring we deliver a superior mould thatmeets exacting design specifications for both fitting and texture.

|

|

|

Mould Trial

When the mould building is completed, we will conduct mould trial to examine and correct any issues. Adjustments are made quickly and efficiently to ensure that your injection mould is delivered ready to run. Once everything is OK, we will provide the customer test samples for final confirmation.

For every mould sampling, we will offer test parameter table and then create checking report within 3 days. Once the sample is confirmed, we will arrange the shipment immediately.

Our full in-house mould making operations are vertically integrated, with little or no outsourcing required other than for specialized heat treating, certain textures, or in some special cases,such as extremely urgent schedule of customer’s project.

|

|

Packing and Shipping

After receiving shipping approval from customers, we will check the mould according to the checklists and conduct about 4 hours trial production before packing to ensure mould can run well at customer’s side after mould shipping. All moulds are vacuum packed so that customers can set up the mould immediately without cleaning.

|

|

HOME

HOME

PRODUCTS

PRODUCTS

SERVICES

SERVICES

CONTACTS

CONTACTS